Automatic coating equipment

Introducing automatic coating systems from the Swiss manufacturer GEMA SWITZERLAND.

Gema Switzerland GmbH is the leading supplier in the field of electrostatic powder coating in the world. The company offers fully automated powder coating lines that meet the highest demands of customers worldwide in every industry.

GEMA Switzerland’s automatic coating equipment guarantees quality powder coating under all circumstances!

OptiCenter 06/07/08 – Powder Management Centers

The OptiCenter powder management center combines state-of-the-art technology with automatic fresh powder feed for fast and clean color changes. The system is the basis for constant and reproducible coating results and significant powder savings.

The OptiCenter has a particularly compact design and the control elements can be arranged flexibly on any side.

Ergonomic and intuitive Interface

Continuous supply of fresh and recycled powder

Fully-automated cleaning process

Quick Color Change and powder feed technology in one very compact device.

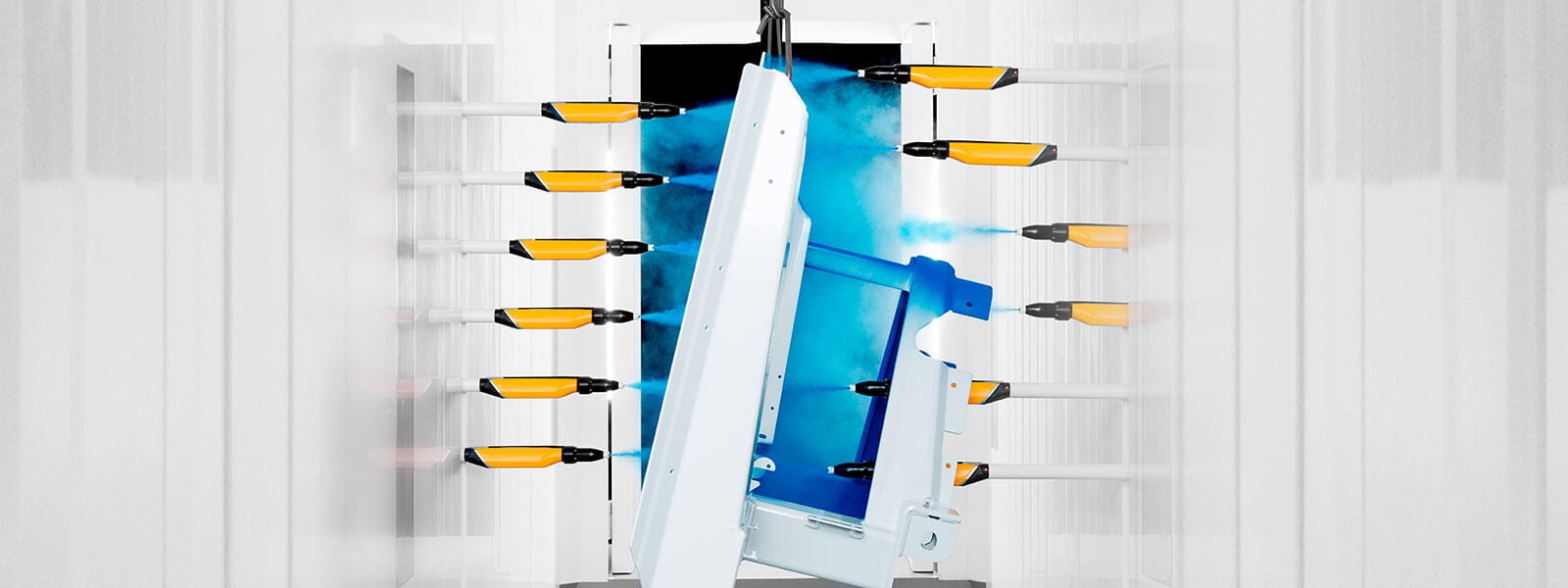

Magic Equiflow – wide range of application, unique cleaning system

It features a sandwich – wall booth construction. As a result powder accumulation is minimized on the booth walls. The booth floor is equipped with an automatic cleaning system to prevent powder deposition.

Extremely uniform airflow creates the ideal conditions for perfect control of the powder application process producing excellent coating results.

MagicCylinder EquiFlow – a unique round design for the quickest color changes!

MagicCompact EquiFlow is a compact color change solution

MagicCompact XXL – the color change solution for extra-large parts

MagicControl 4.0 for automatic coating equipment – the pioneering interface for Smart Factory Automation

With MagicControl 4.0 all system components of the coating line can be linked and controlled, warnings and error messages monitored, application programs stored and production data generated.

The comfortable touch screen interface with its self-explanatory icons is clear and simple to use for every operator.

The coating parameters can be individually adapted to different powder types or applications. The result is constant coating quality and minimal powder consumption.

MagicControl 4.0 can be integrated into existing systems and production

infrastructures, allowing a bidirectional data exchange for an effective production process.

Dynamic Contour Detection – Scan & Spray

Dynamic Contour Detection eliminates the requirement for the programming, extending automated coating capabilities and process improvement to new levels.

Automated object scanning process and application program selection Scan: Dynamic shape detection

Regardless of the product size and complexity, the system delivers unequaled application consistency and quality, automatically.

AP01.1 – application pump

Stable and reproducible powder output

Smart Inline Technology with its straight path design leads to a consistent, gentle powder flow for uniform film thickness and repeatability.

Maintenance was never so easy and fast

The optimized design with quick-release connections for powder hose as well as the tool-less replacement of wear parts reduces production downtime and labor time

Thanks to Smart Inline technology, the powder paint supply remains constant over a long period of time and ensures high coating quality.

SIT

Fastest response behavior for highest coating efficiency

Ergonomics

Space – saving design for an ergonomic workplace

DCD

Highest application flexibility

Controls

Centralization of all parameters

E-App

Transparent and better controllable coating process

EquiFlow

Perfect coating conditions and quick color change