Drying and curing ovens

Polymerization represents the final and critical stage of the powder coating process. Errors at this stage, such as improper temperature control, unsuitable heating methods, or inadequate air circulation, can nullify all prior efforts in cleaning, preparation, and painting of the surface.

A quality and properly selected oven is the key to achieving flawlessly painted products.

Reliable ovens are required by small paint shops as well as extensive facilities equipped with automated painting lines.

Box ovens

Ovens are equipped with doors on one or both sides presenting an ideal solution for manual painting lines. They enable the simultaneous placement of numerous parts along the parallel guides of the overhead conveyor. Superior thermal insulation and fully enclosed doors contribute to reduced energy consumption.

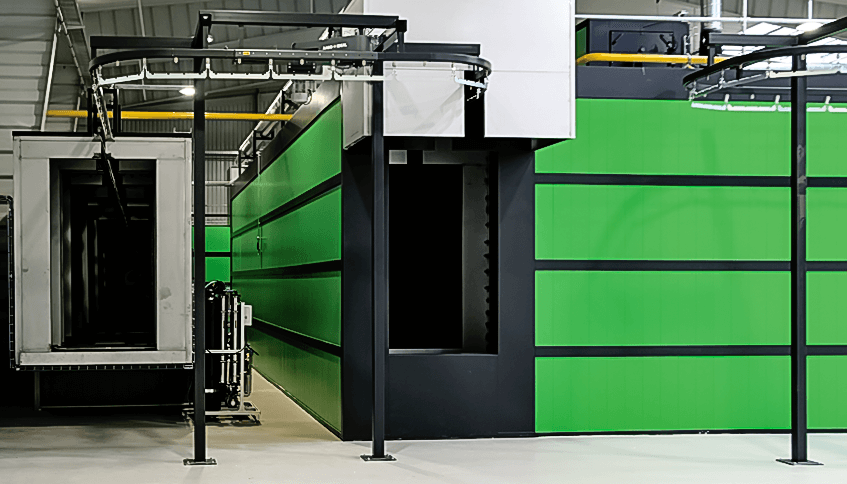

Tunnel ovens

The products or items pass through the oven either continuously or by power & free conveyor with stops. The ovens are convection ovens in which high air circulation leads to quick and effective heat transference to the product.

Thanks to exceptional thermal insulation and the use of a unique technology designed and constructed to create the lowest possible heat transference from the inside to the outside, AABO-IDEAL furnaces provide fast heating and low energy consumption.

Intensive and uniform air circulation

Compact and high performance

Choice of energy sources: electricity, natural gas, liquefied gas, or diesel

Depending on your needs, requirements and production conditions, our team of experts will select the optimal oven option and configuration tailored to your unique circumstances.